AQUATRON-6 waterproofing

The effect of water resistance is formed due to the reaction taking place inside the structure of the building material between the components of the waterproofing composition and the components of the protected material. The chemical components of the waterproofing mixture penetrate deeply into the material through capillaries under the action of osmotic (capillary) pressure. As a result of chemical reactions, insoluble needle-shaped crystals are formed, which fill the capillaries and shrinkage cracks, while displacing water. This process occurs both in the direction and against the pressure of the water.

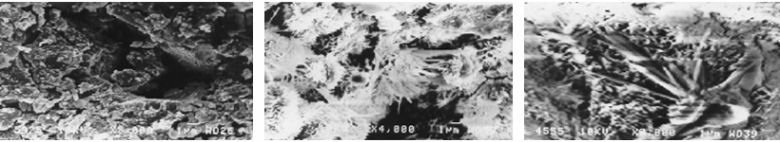

The visual change in the structure of the waterproofing mixture in contact with the structure, measured by an electron microscope with a magnification of x104, shows needle formation in the capillaries to a depth of more than 150 mm.

| a) Untreated concrete | b) At a distance of 150 mm from the coating | c) At a distance of 100 mm from the coating |

Application of Aquatron-6 allows the following:

|

|

How to use AQUATRON-6 waterproofing compound

1. Surface preparation

Prior to application of the compound, clean the surface from dirt, grease, paint, and other impurities in order to open the system of capillaries and micro cracks. Prior to application, clean the surface from dirt and sprinkle with water to full saturation (until no more moisture can be absorbed).

Prime the prepared surface with a compound (1 part of dry composition to 1 part of water) and wait for 5-10 minutes.

2. Preparation of waterproofing compound

Pour the compound in the amount necessary for preparation of mixture volume required for 45 minutes of work into container; thoroughly stir with water until you get a homogeneous mix.

3. Application of the compound

The base compound is applied to the surface with a brush, trowel or by shotcrete method with a consumption depending on the purpose. Aquatron-6 is an easy to use, durable, non-toxic during application and use material for waterproofing; it has no adverse health or environment effect, and is approved for use in contact with drinking water throughout the territory of the Customs Union.

The materials have a long shelf life (24 months from date of manufacture).

Features of penetrating waterproofing materials of AQUATRON series

AQUATRON formula has components optimized both chemically and physically. For example, because of special mechanical treatment, the sand contained in this material transforms from inert filler into an active component that increases adhesion with the protected surface and its durability.

Waterproof effect occurs due to the reaction between the components of the compound and components of the protected material that takes place within the structure of the construction material. The chemical components of Aquatron-6 penetrate deeply into the material through capillaries under osmotic (capillary) pressure.

Chemical reactions result in formation of insoluble needle-shaped crystals that fill the capillaries and shrinkage cracks, displacing water. This process occurs both down the water pressure trend and backwards.

The visual change in the structure of waterproofing compound in contact with the structure measured by an electronic microscope shows the penetration of the compound up to 150 mm in depth.

The higher the moisture content of the concrete structure is, the more effective is the penetration of active chemical components into the body of concrete.

AQUATRON-12 concentrated waterproofing compound is designed for waterproofing of monolithic concrete and reinforced concrete structures during concrete pouring.

|

Basic dry mix quality indicators |

|

|---|---|

|

Appearance |

Gray-colored powder, shade not standardized |

|

Humidity, %, not greater than |

0,1 |

|

Greatest size of filler grain, Dmax, mm, max. |

0,63 |

|

Content of grains of the greatest size, %, max. |

0,5 |

|

Basic quality indicators of ready-to-use mixture |

|

|

Setting time, hours: - beginning, not earlier than - end, not later than |

2 5 |

|

Consumption of mixing water, l/kg (g/kg) |

0,22-0,26 (220-260) |

|

Basic quality indicators of hardened solution |

|

|

Compression strength of material, MPa, at least |

30 |

|

Water impermeability of the material, W, grade, at least |

16 |

|

Freezing resistance of the material, cycles, at least |

F300 |

|

Increase in grade due to improved freezing resistance of concrete treated with the compound, at least |

2 |

|

Increase in grade due to improved water resistance of concrete treated with the compound under direct water pressure, degrees, at least |

2 |

|

Increase in grade due to improved water resistance of concrete treated with the compound at back pressure of water, degrees, at least |

2 |

|

Strength of adhesion with concrete bottom, MPa, at least |

1,1 |

|

Resistance of concrete of protected structure to dealkalization (first type of corrosion), time of destruction of a 3‑mm layer, years |

100 |

|

Improved corrosion resistance of concrete of protected structure in an acidic environment (рН ≥ 3) (second type of corrosion), times |

3 |

|

Sulfate resistance (3rd type of corrosion), degree, at least |

1 |

|

Operation temperature, °C - minimum - maximum |

- 60 + 250 |